Step-By-Step Bathroom Renovation Guide (Based on a Real London Project)

In this project, we’re ripping out a tired 1970s bathroom and turning it around in just 10 days.

Renovating a bathroom in a lived-in home is always a challenge. When it’s the only bathroom in the house, the pressure is even higher.

This guide follows a real bathroom renovation in a 1970s London property, completed in around 10 days of intense work. You’ll see exactly what happens at each stage:

-

Rip-out

-

First-fix plumbing and electrics

-

Underfloor heating and self-levelling

-

Floor tiling

-

Wall panelling

-

Second-fix shower, basin, toilet and radiator

-

Final sealing and handover

If you’re planning your own bathroom renovation, you may also want to see the full price breakdown here…

And if you’re ready to get professional help, you can explore our Bathroom Renovation London service page here…

LAST UPDATED: DECEMBER 04, 2025

🗂️ Bathroom Renovation Timeline Summary (10-Day Real Project)

Day 1 — Rip-Out & Strip-Back

Remove bath, basin, toilet, tiles, flooring and radiator. Clear debris and expose all pipework.

Day 2 — First-Fix Plumbing

Re-route hot/cold feeds, adjust wastes, fix knocking pipes, chase walls, and position new bath/vanity/toilet layout.

Day 3 — First-Fix Electrics

Install lighting layout, chase shower feeds, add extractor fan ducting and wiring.

Day 4 — Cistern Frame & Box Sections

Build boxed areas, install concealed cistern, prepare flush pipe, align heights and board structural frames.

Day 5 — Floor Preparation

Prime timber floor, install 6mm Jackoboard, level boards, and screw down at 300mm centres.

Day 6 — Underfloor Heating & Self-Levelling

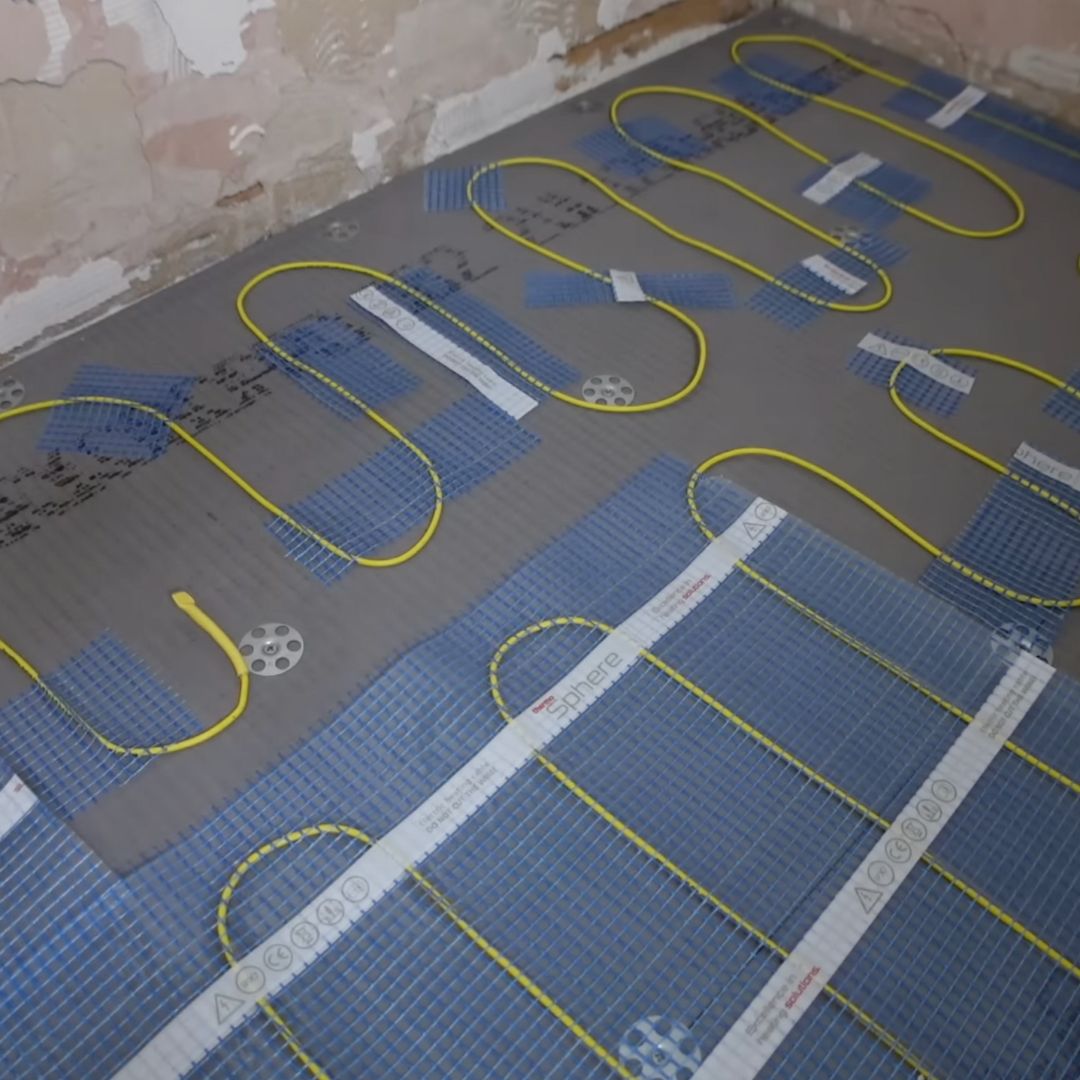

Lay heating mat, cut mesh for layout, install floor sensor, embed in self-levelling compound and wire thermostat.

Day 7 — Floor Tiling

Lay flexible adhesive, set out tiles, grout and prepare finished floor for second fix.

Day 8 — Wall Panelling

Cut and fit laminate fibre boards, install trims, seal joints, and finish shower/bath zones.

Day 9 — Full Silicone Sealing

Seal panel joints, corners, floor junctions, window reveals and bath edges for a watertight finish.

Day 10 — Second-Fix & Handover

Install shower, screen, vanity, basin, tap, toilet, flush plate, radiator and final silicone. Bathroom ready for use.

Day 1 – Bathroom Rip-Out (The Messy But Necessary Start)

Every renovation begins with a full rip-out. In older London homes, this stage often reveals hidden surprises — old carpet in the bathroom, layers of tiles on top of tiles, and outdated pipework.

Typical rip-out tasks include:

-

Removing the bathroom door to create working space

-

Lifting out the old bath

-

Disconnecting the waste, hot, and cold feeds

-

Taking off the first row of tiles around the bath

-

Removing basins, taps, and the toilet

-

Taking down radiators

-

Clearing all debris and loading it into a skip

This stage exposes the real condition of the room and reveals what needs to be corrected during the first-fix.

USEFUL LINKS / CALCULATORS

Removing the Old Bath and Fixtures

Once the water is isolated, the old bath can be disconnected from the waste, taps, and feet. In some older London homes:

- Previous owners tiled over old tiles

-

Trap fittings contain years of grime

-

Floors may hide large, poorly cut openings

The bath is lifted out (or smashed up if cast iron), and the plumbing below becomes accessible for correction and re-routing.

The basin and toilet follow next. Rusted screws, faulty isolation valves, and unpleasant smells are all part of the process — but removing everything is essential for a clean, safe first-fix.

Removing Tiles and Preparing the Walls

With fixtures out, the tiles come off. Sometimes homeowners discover:

-

Two layers of tiles

-

Weak bonding

-

Hidden damp patches

-

Inefficient wall boarding

Proper PPE is crucial here (gloves, eye protection, ear protection), as tiles are sharp and removal can be loud and dusty. Once the walls are bare, you can clearly plan pipe routes and fixture positions.

Day 2 – First-Fix Plumbing and Pipe Re-Routing

Now the bathroom layout can be planned properly.

The installer decides:

-

Where the new bath will sit

-

Mixer valve height

-

Shower head height

-

Vanity position and waste route

-

Toilet position and cistern frame height

-

Radiator or towel rail location

Once marked out, the first-fix plumbing begins.

Typical tasks include:

-

Chasing walls for new hot and cold feeds

-

Replacing old solder joints

-

Correcting pipework knocking or movement

-

Running waste pipes under floors

-

Installing isolation valves

-

Repositioning radiator pipe tails

-

Adding reinforcement (sistering joists) before drilling

Older homes often need structural adjustment (such as strengthening joists) before routing new waste pipes safely.

First-Fix Electrics – Lights, Fan, Cabling

After plumbing comes electrics. In this project, the ceiling was marked for:

-

Four IP65 downlights

-

One additional light over the toilet area

-

A new inline extractor fan located in the loft

This improves brightness, reduces moisture issues, and brings older bathrooms up to modern standards.

Building Box Sections and Concealed Systems

A big part of modern bathroom design is concealed systems and neat boxing.

Tasks in this stage:

-

Building a shelf or box at the end of the bath

-

Constructing a stud frame for the concealed cistern

-

Positioning the toilet to line up visually with the window sill

-

Installing the concealed cistern and testing it

-

Reinforcing flush pipework

-

Ensuring future tiling will align perfectly

Dummying up the toilet and bath is crucial. This ensures the final installation fits precisely and avoids issues later.

Waste Pipes, Pan Connector & Floor Preparation

Next comes the waste system adjustment:

-

Cutting back and replacing the soil pipe

-

Installing a flexible pan connector

-

Ensuring fall and alignment

-

Preparing floor space for new pipe runs

-

Adding insulation or lagging to prevent pipe contamination

This is also where old rubbish under the floor gets removed — a common find in older London houses.

Day 3–4 – Ceiling Painting and Moisture-Proof Boarding

Once first-fix plumbing and electrics are complete, the room starts to come back to life:

-

Mist coat applied to the ceiling

-

Moisture-resistant bathroom paint added

-

Moisture-resistant plasterboard fitted to box sections

-

Final checks on plumbing isolation valves

-

Preparing walls for tiling

This creates a clean, sealed base for the second-fix stage.

Day 5 – Floor Preparation and Insulation

Day 5 focuses on creating a solid base for underfloor heating and tiles.

First, the timber floor is:

-

Marked where the bath footprint will sit (no heating under the bath)

-

Primed with SBR to seal the floor and help adhesive bond properly

Then 6mm Jackoboard insulated backer boards are cut and dry-laid in a brick pattern with staggered joints. Once ready:

-

Flexible tile adhesive is applied with a 6mm trowel

-

Boards are bedded into the adhesive and levelled

-

After curing, Jackoboard washers and screws are added at roughly 300mm centres

The result is a level, insulated and solid floor, ready for underfloor heating mats.

Day 6 – Installing Electric Underfloor Heating

Now the underfloor heating goes in.

The mat used is a Thermosphere electric underfloor heating mat. The process includes:

-

Testing resistance with a multimeter before installation

-

Comparing readings to the manufacturer’s tolerance in the instruction manual

-

Marking out where the vanity and toilet will sit (no need for heating under them)

-

Rolling out the mat with 50mm spacing from walls and between cables

-

Carefully cutting only the mesh (never the heating cable) to change direction

-

Avoiding laying cables over fixings like washers

In a small room, some cable is removed from the mesh and re-fixed with extra mesh pieces to get full coverage.

Installing the Floor Sensor and Cold Tail

A small channel is routed into the Jackoboard for the floor temperature sensor:

-

The conduit is set between two heating cables

-

The sensor is fed down from the thermostat location until it pops out at floor level

-

It is then pulled back slightly and capped

-

The heating mat is laid back over the top

The cold tail – the power feed from the thermostat to the mat – is also chased into the board and taken up the wall in conduit, then secured with all-round band.

Another resistance test is carried out to ensure nothing has been damaged during installation.

Self-Levelling Compound Over the Heating Mat

To protect the cables and create a perfectly flat surface for tiling, a flexible self-levelling compound suitable for underfloor heating is used.

Steps:

-

Expanding foam is used along the bath edge to stop compound flowing under the bath area

-

The compound is mixed with clean cold water to a smooth, lump-free consistency

-

After resting briefly, it’s poured over the mat

-

A trowel spreads the compound into corners and across the floor

-

A spiked roller removes air bubbles and helps the compound settle evenly

Small areas where the mat slightly shows through are not a problem. Tile adhesive will cover them. After a final resistance test, the floor is left to dry.

Wiring the Underfloor Heating Thermostat

Once the compound has set, the thermostat is wired:

-

Three cables are present at the back box: supply, cold tail, and floor sensor

-

The outer sheaths are stripped, conductors prepared and connected as per the manufacturer’s wiring diagram

-

The backplate is fixed to the box

-

The thermostat face is clipped on

At this point, the underfloor heating is fully installed, tested and wired, ready for use once tiling and grouting are complete.

Day 7 – Tiling the Floor

With the self-levelling compound dry, floor tiling begins.

Although there is a separate in-depth video for the tiling process, the key steps are:

-

Setting out the room to minimise small cuts in visible areas

-

Using appropriate flexible tile adhesive over the levelling compound

-

Working carefully so as not to disturb or damage the underfloor heating below

-

Maintaining consistent joints and levels across the floor

Once grouted, the heated tiled floor becomes a major comfort upgrade in the finished bathroom.

Day 8 – Wall Panelling Instead of Traditional Tiling

You may notice that the walls still look messy with old tile adhesive. Here’s why.

Instead of retiling the whole bathroom, cement grey fibre boards (such as Fibo or similar laminate bathroom panels) are used:

-

They are quicker to install than tiles

-

They can go over old adhesive as long as the wall is solid and not blown

-

They create a clean, modern, grout-free finish

Although more expensive than tiles, they save a huge amount of time, which is vital on a 10-day renovation in a live family home.

Cutting and Fitting the Wall Panels

The process for the wall panelling includes:

-

Measuring multiple points for height to account for any ceiling unevenness

-

Measuring width and pipe positions carefully

-

Cutting aluminium external corner trims to height

-

Cutting panel boards with a track saw or circular saw with a good blade

-

Drilling neat holes with a hole saw for radiator pipes and other penetrations

The panels use a tongue-and-groove style joint:

-

The male tongue is sealed with a bead of sanitary silicone

-

Boards are offered up and clicked into the female groove

-

A hybrid polymer adhesive is applied to the back or the wall in thick beads

-

Boards are pressed into place and adjusted so joints are tight

Any silicone that squeezes out is smoothed using a silicone tool and a light spray of water, leaving a neat, sealed joint.

Sealing Corners, Bath Edges and Shower Area

In the shower and bath zones, waterproofing is critical:

-

A generous bead of sanitary silicone is applied in internal corners before boards are pushed together

-

The joint between the laminated panel and bath edge is sealed twice: once behind and once at the visible face

-

Internal corners are sealed without plastic corner trims, reducing potential leak points

This double-seal approach helps prevent water ingress and protects the boards from swelling or blistering over time.

Finishing the Panelling and Fiddly Details

Over roughly two days of panelling:

-

All main walls are covered

-

Box sections are clad

-

Shower area is panelled fully

-

Fiddly cuts around windows and small details are completed

-

One missing trim is noted and ordered to complete the last edge later

Because older rooms are rarely perfectly square, the fiddly areas and box sections take time, but the end result is a seamless, modern finish.

Day 9 – Full Silicone Sealing and Final Prep

Day 9 is all about finishing the waterproof envelope and preparing for second fix.

Tasks include:

-

Sealing around the bath

-

Sealing all panel joints

-

Sealing at the floor and wall junctions

-

Sealing around window boards and trims

Doing this before second-fix makes it far easier to achieve a professional silicone finish, with full access to corners and edges.

The bonding and electrical connections for the underfloor heating are also completed and checked, so the floor is ready to be brought into service after grouting and curing times.

Day 10 – Second-Fix and Final Push to Finish

Day 10 is the big push: the goal is to get the bathroom usable by the family that night.

The key tasks are:

-

Fitting and testing the shower and riser

-

Installing and sealing the shower screen

-

Installing the vanity, basin, tap and trap

-

Installing and fixing the back-to-wall toilet and connecting the concealed cistern

-

Fitting the flush plate and checking both flushes

-

Hanging and connecting the towel radiator

-

Final silicone sealing and checks

Even though a bit of snagging remains afterwards, the important milestone is met: the bathroom is safe, functional and fully usable by the end of Day 10.

👉 Need a quick quote?

Try our Bathroom Renovation Services London to get an instant estimate.